Lowest Prices in the US

Our pricing is comparable to going factory direct. We will beat any US company's price!

25 Piece Minimum

Our minimums for pins are the lowest in the industry. If you need even fewer than 25, we'll work with you.

6 Enamel Colors Free

Most companies only give 4 free enamel colors, but we set the precedent with 6.

No Hard Enamel Up-Charge

Express yourself freely! We believe that beautiful, high-quality hard enamel pins shouldn't cost extra.

Get a Quote

Submit a sketch or idea and tell us basic details about your pins, such as quantity, size, and the date you need them. You'll receive a customized price within 1 minute.

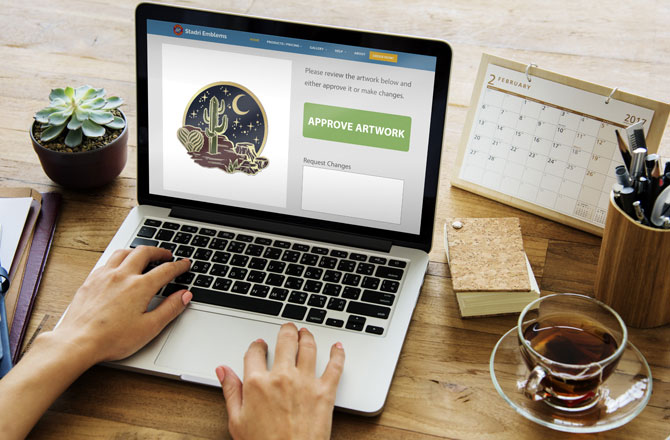

Approve Your Proof

Your order includes full design services and professional advice in order to ensure your final product will look amazing. We will not proceed until you fully approve of the design.

Receive Your Order!

Sit back and relax and let us work our magic! We have over 40 years of experience turning your beautiful ideas into reality. Impeccable quality takes time. Expect to receive your pins in 4-6 weeks.

Gallery

See our quality for yourself while you check out pins we made for our customers.

Help With Design

Ordering your own custom pins doesn’t have to be intimidating.

Manufacturing Details & FAQ

We eliminate the mystery surrounding how your pins are made.

Community & Events

Check out our past and future events and find out why we are truly a part of the pin community.

Enamel Pin Pricing

Your search is over for top-quality enamel pins that won't break your budget. If you find a lower price from any US competitor, we will beat it!

| 25 | 50 | 100 | 250 | 500 | 1000 | |

| 0.50" | $5.12 | $2.88 | $1.96 | $1.29 | $0.95 | $0.72 |

| 0.75" | $5.25 | $3.39 | $2.19 | $1.45 | $1.05 | $0.85 |

| 1" | $5.35 | $3.49 | $2.25 | $1.62 | $1.12 | $0.95 |

| 1.25" | $5.49 | $3.63 | $2.45 | $1.69 | $1.25 | $1.05 |

| 1.50" | $5.95 | $3.83 | $2.55 | $1.85 | $1.31 | $1.16 |

| 1.75" | $6.69 | $4.14 | $2.75 | $1.99 | $1.44 | $1.33 |

| 2" | $8.38 | $4.64 | $3.49 | $2.32 | $1.69 | $1.59 |

| 2.25" | $8.49 | $5.25 | $3.63 | $2.62 | $1.99 | $1.85 |

| 2.50" | $8.75 | $5.49 | $3.73 | $2.99 | $2.29 | $2.12 |

| 2.75" | $9.29 | $6.15 | $4.24 | $3.49 | $2.39 | $2.29 |

| 3" | $10.58 | $7.47 | $4.95 | $3.73 | $2.98 | $2.85 |